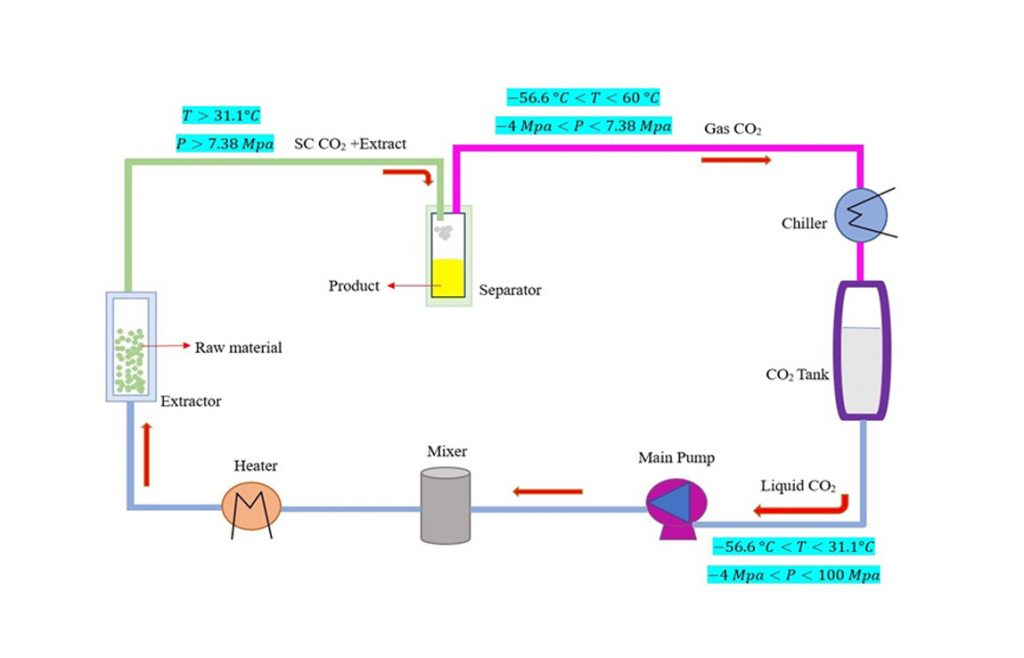

Supercritical fluid extraction technology (SFE) is recognized as one of the most innovative and efficient methods of extracting bioactive compounds from natural resources, especially in the pharmaceutical and food industries. This method is rapidly expanding due to its significant advantages over traditional methods. In this text, we will explore the scientific principles, benefits, applications and challenges of this technology.

Scientific Principles of Supercritical Technology

Supercritical fluid refers to a state of matter that is at a temperature and pressure higher than its critical points. In this case, there are simultaneous liquid and gas characteristics. For example, carbon dioxide (CO₂) reaches supercritical state at temperatures above 31 degrees C and pressures above 73 times. In this case, CO has a density close to that of a liquid and a viscosity similar to that of a gas, which makes this fluid capable of dissolving different compounds.

advantages of Extraction with Supercritical Fluid

- Maintain quality and purity

- Absence of harmful solvents

- High performance SFE

- SELECTABILITY